PROPERTIES

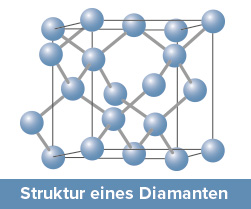

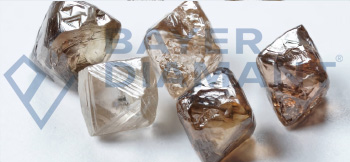

Diamond is a mineral consisting of pure cubic crystallized carbon. The chemical bonding of the carbon atoms makes the diamond the hardest known material. Thus the diamond is the only mineral to receive level 10 on the Mohs scale, which describes the scratch hardness of a mineral. The carbon atoms are connected in a regular crystal lattice and form the typical octahedron, dodecahedron or cube shape of a diamond with curved surfaces and rounded tips.

The weight of a diamond is measured in carats, the weight unit for gems.

1 carat = 0.2 g

ORIGIN

Natural diamonds are formed from graphite in an endothermic reaction deep inside the earth at temperatures of 1250–1500 °C and enormous pressure. Diamonds are found in kimberlite, the so-called parent rock, which is brought to the earth‘s surface by volcanic activity.

APPLICATION

Different types of diamonds can be used in industrial applications. In addition to the careful selection of the right diamond for the respective area of application, precise grinding is also important to ensure a long service life and the best possible results.

THE DIAMOND CUT

Precondition for an excellent machining result and a long service life. In the case of monocrystalline diamonds, the crystal structure of the stone must be taken into account and processed in such a way that the crystal lattice and cutting edge are perfectly matched – a demanding task that requires know-how and sensitivity.

WHAT EXACTLY IS SINTERING?

Under high temperature and high pressure, the heterogeneous material mixture is used to produce the most homogeneous material possible with a defined property.

THE DIFFERENT TYPES OF DIAMONDS

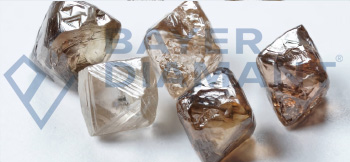

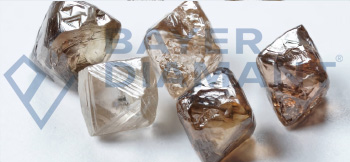

Natural diamonds

are not only used to adorn precious pieces of jewellery, but are also a widely applied material in industry for the precise processing of versatile materials. Diamonds from natural deposits have a mono-crystalline structure that makes the stone the hardest known material and enables high-precision cutting edges. Due to the different properties and qualities, natural diamonds are selected for industrial use by experienced specialists. Natural diamonds are mainly used as seam stones and octahedral or dodecahedral.

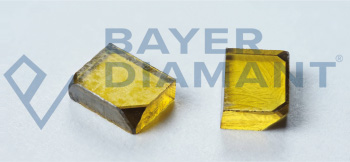

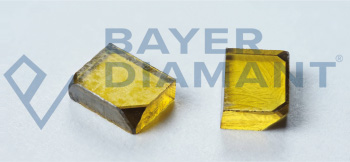

Monocrystalline Diamonds (MCD)

synthetic diamonds are the industrially produced equivalent to natural diamonds. Thanks to modern manufacturing processes, diamonds can be produced in a measureable quality with properties comparable to those of natural diamonds. Just as with natural diamonds, the cutting edge, which is carved out of a single crystal block, enables high precision and surface quality.

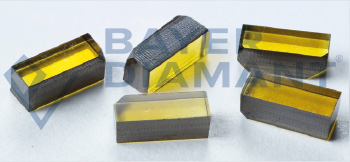

Polycrystalline Diamonds (PCD)

are formed when synthetically produced diamond dust binds under high pressure in a sintering process to form a diamond. The hardness of the material corresponds approximately to the hardness of mono-crystalline diamonds. Sintering leads to a high fracture toughness, which makes the diamond material less sensitive to Impacts.

CVD diamonds

are synthetically produced by coating substrates by chemical vapour deposition (CVD). In a vacuum chamber, a diamond layer is deposited on the substrates (e.g. tungsten carbide base body). A gas mixture of methane and hydrogen is the starting material.

OVERVIEW OF THE DIFFERENT TYPES OF DIAMONDS:

CVD-cutting

MKD-cutting

MKD-rods

Flat seam diamond triangles

PCD triangular diamonds

CVD triangular diamonds

MCD

MCD octahedron

Large arched natural diamond triangles

PCD round cuttings

CVD rods

MCD rods

MCD round cuttings

Natural octahedron diamond

Diamond grain

OVERVIEW OF DIFFERENT TYPES OF DIAMOND DRESSERS:

Profile Dressers

are used to give grinding wheels a defined shape. The diamonds in the dressers are precisely ground to a predetermined profile. The radius and angle of the diamond are important.

AVAILABLE DIAMONDS:

Flat seam diamond triangles: preferred for 40° (small) radii

Large arched natural diamond triangles: preferred for 60° (large) radii

CVD cutting: low-priced alternative to natural stones

MCD diamonds: alternative to natural stones with the same service life as natural stone

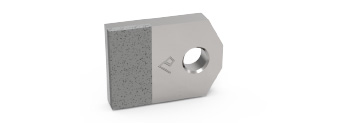

Dressing Plates (Needle Tiles)

are used for dressing straight grinding wheels and for profiling for high demands. In dressing plates, the diamonds made of MKD, CVD or natural needles are placed in a hard coating or metal binding before they get sintered.

AVAILABLE DIAMONDS:

MCD rods: different metal bonds, depending on application and customer requirements

CVD rods: different metal bonds, depending on application and customer requirements

Dressing wheels

are mainly used for straight dressing, but can also be used for profiling with single-row design. Diamond needles or selected diamond seam stones are used.

AVAILABLE DIAMONDS:

Flat seam diamond triangles

Natural stone-diamond abrasive grain

MULTIGRAIN DRESSING TOOLS / MULTIGRAIN TILES /

MULTIPOINT TILES / NEEDlE TILE

are suitable for single profile coarse dressing of straight and even grinding wheel surfaces without scoring. Diamonds of selected quality are set by hand in several layers and held together with a sintered bond adapted to the application. Alternatively, diamond powder or diamond grain is sintered into a dressing element. For the needle tiles the diamond

needles are sintered into a dressing element.

AVAILABLE DIAMONDS:

Natural diamond grain: Diamond grain size of D46–D1181

Multigrain tile: Broken diamond grain

Grain tile: Manually set unbroken diamond grit

Needle tile: Diamond needle (Natural diamond)

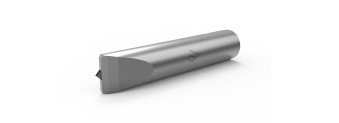

Singlepoint Dressers

are used for dressing straight grinding wheels and consist of an octahedron- shaped diamond which is soldered into a holder. The tips of the diamond can be natural or ground.

AVAILABLE DIAMONDS:

Natural octahedron diamond: 0,33–2,5 carat

Due to lower dressing pressure it is possible to dress malleable grinding wheels

Triangular dresser

The PCD or CVD dressers on carbide carriers can be used several times due to their triangular shape. Application: Dressing of grinding wheels and internal grinding wheels.

AVAILABLE DIAMONDS:

PCD triangles, CVD triangles:

> common holders available

> flexibility through interchangeable holders and diamond triangles

> diamond radii are flexibly interchangeable